4 min read

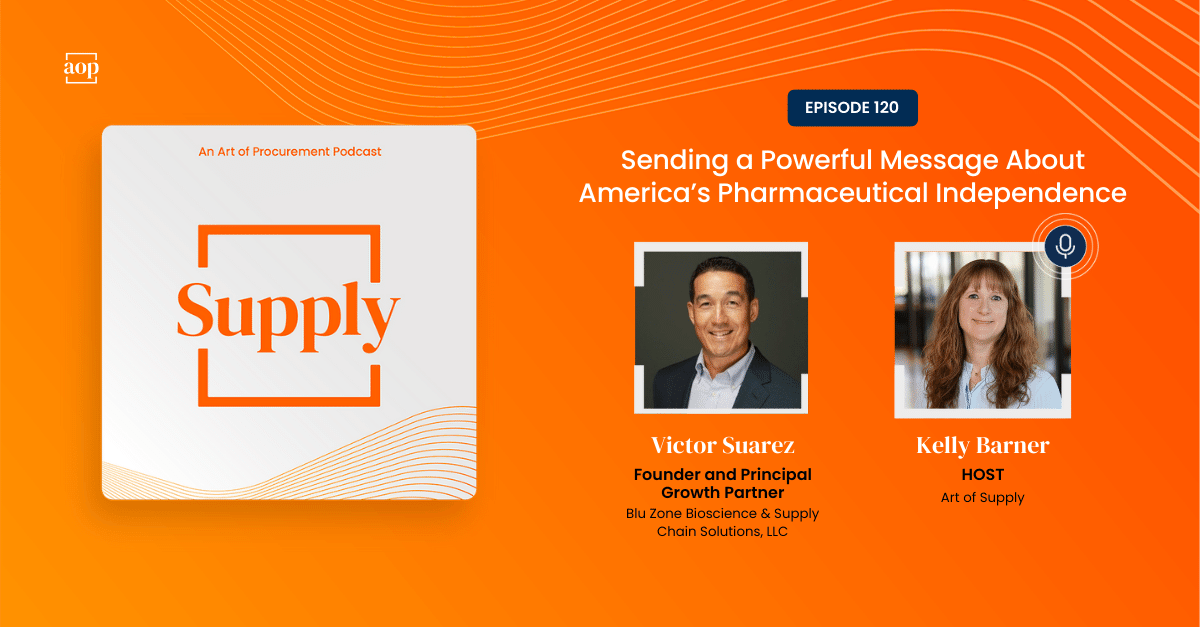

Sending a Powerful Message About America’s Pharmaceutical Independence

Kelly Barner : Updated on December 1, 2024

Victor Suarez is a retired Colonel from the United States Army. He worked for the U.S. Department of Health and Human Services (HHS) before becoming the Lead Vaccine Program Manager for Moderna’s COVID-19 vaccine during Operation Warp Speed (2020-2021). Today he is the Founder and Principal Growth Partner at Blu Zone Bioscience & Supply Chain Solutions, LLC.

On April 30th, 2024, he was invited to testify before the U.S. Senate Committee on Armed Services, Subcommittee on Personnel about the Department Of Defense’s efforts to ensure service members would have access to safe, high-quality pharmaceuticals.

In this month’s Art of Supply interview, I had the opportunity to speak with Victor about the problems and solutions he sees within the pharmaceutical supply chain.

The Sources of Today’s Shortages

The Hatch Waxman Act, passed in 1984, played a key role in facilitating the entry of generic drugs into the U.S. market.

This law facilitated the entry of generic drugs into the U.S. market by compensating the companies who had invested in research and development (R&D) by delaying generic drug eligibility. Unfortunately, it did not foresee its own effect. Hatch Waxman should have also taken steps to prevent the downward spiral of profitability associated with generic drugs.

“Hatch Waxman was passed to provide a faster, more efficient pathway for generic medicines to be approved through an abbreviated new drug application,” Victor explained. “But in the eighties, you also saw many industries migrate to a global supply chain manufacturing economy. There was this big push to make products cheaper and more efficiently overseas so that companies could continue to make profit.”

This thinning of margins drove generic drug production abroad, most notably to China and India. Over time, that optimization for the sake of lower costs created the troubling foreign dependence that we face today.

China is currently the source of 20 percent of the active ingredients in vital medicine (known as APIs) and 45 percent of key source materials (KSMs) are sole sourced from China.

“I would even say it’s even worse than that,” Victor pointed out. “Those 20 or so percent of APIs are associated with about 60 vital medicines in the United States that are solely sourced from China. That means there’s not even a secondary source of supply in the world.”

From his perspective, this puts the United States in a precarious situation. “If there was a geopolitical event or tensions in the South China Sea over Taiwan policy, et cetera, they could withhold key materials or these key active pharmaceutical ingredients that directly impact U.S. healthcare for some of the most critical medicines that Americans rely on.”

Sole sourcing is usually associated with elevated risk levels, but in this case our health and well-being depend upon uncertain trading and geopolitical relationships.

What Does it Mean to Be Made in the U.S.A.?

The straightforward answer to America’s dependence on foreign pharmaceutical production is to make more drugs domestically, but defining what this means is not simple.

Senator Rick Scott asked Victor about this during his testimony: What is the primary obstacle to moving pharmaceutical supply chains away from China? In February of 2020, on the eve of the COVID pandemic, a U.S. Court of Appeals ruling allowed ‘mixed in the U.S.A.’ to count as ‘made in the U.S.A.’

“What they ended up doing was they established subsidiaries in the United States where they would still make all the APIs and all the other ingredients (the bindings, the fillers, and the colorings of those medicines) and they made them overseas, for example, in a Chinese plant. They shipped all those things over in large barrels to a subsidiary in the United States where they just did the final step of the compounding and the mixing, and then the packaging and labeling of that medicine. And then they said, oh, it’s made in America,” Victor told me.

“I think the real big message I was trying to relay to Senator Scott was, you can’t do any of this purchasing or preference for an American-made medicine until you address this legal loophole from a legislative standpoint. Because if you don’t do that, then they’re going to find ways to circumvent what you’re trying to do.”

My speculation in reply was about timing. If the ruling had been even 30 or 60 days later (or further into the pandemic) would the decision have been different? Unfortunately, we will never know the answer to that question for sure.

Finding a Workable (and Affordable) Solution

Victor offered three ways to mitigate the risk associated with prescription drug shortages:

Building a stockpile of necessary APIs and KSMs. He advocates for storing raw materials because they have a longer shelf life in their unmixed forms, potentially lasting 3-4 times as long. This would function similarly to the country’s strategic petroleum reserves, giving the United States more supply resilience in uncertain global markets.

Make purchasing decisions based on quality, not just price. This is a recommendation that will speak to the heart of every procurement professional, regardless of industry. If we don’t allow these drugs to differentiate themselves, low cost is likely to be the deciding factor. “What we know from independent third-party testing is that that is just flat out not true scientifically, chemically that’s just not true. What I would concede and say is that there are a number of high-quality generic medicines that are made almost to the same degree as the brand name drug. The problem is everybody is blind to that data unless they see the testing data.”

Provide for a general increase in transparency. What patients and consumers don’t know about the U.S. drug supply today could definitely hurt them, or worse. Providing a rating system and visibility into cost differentials, most of which amount to little more than a few percent in increased cost for the consumer, might not seem that impactful, but it would at least give them the choice.

As we wrapped our conversation, I asked Victor for two final takeaways, one from the supply chain point of view, and one that was a bit more human. Pharmaceutical supply chains are often a matter of life and death after all. His response brought all of this into perfect focus:

“What I’d ask you to do is think about whether you want the highest quality possible medicines for your family members, yes or no? It is as simple as that. Would you like to see more transparent data on the quality attributes of those medicines so that you can have a better idea and a conversation with your pharmacist and your doctor about why you might be having complications with a medicine that when you were on a different one a couple months ago, you were having no issues?

These things are not simple, but these are things that have not been transparent to the American public. And so I’m working with the team to make that as transparent as possible.”